Machine Tending

Job shop owners consistently rank the ability to find qualified machinists as the number one problem they face as a business owner.

While high production manufacturing businesses solved their labor shortage issue with automation decades ago, automation for the high-mix/low-volume manufacturing environment of job shops had remained elusive.

ProCobots was founded to make job shop automation practical: It needed to be flexible, easy to

program, easy to move to multiple machines, compact without the need for intrusive safety fences, and

able to work WITH the machinists instead of replacing them.

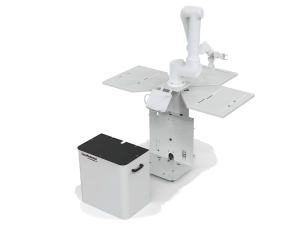

EasyWork

- Built for simple machine tending

- UR3 and UR5 can be mounted

- Adapter system for UR10

- Mobile between machine jobs

- Docking station for precise machine tending

- Different type of part trays available as option

- The EasyWork platform is compliant to ER+ Software

- Hartinger connector for UR control can be mounted on the rear.

EasyPedestal

- Small footprint for tight workspaces

- Built from quality steel for durability and stability

- Includes compartment for robot control unit

- Fits up to three trays

Specifications

| Height | Weight | Features |

|---|---|---|

| 925 mm | 80 kg | T-pad bracket, controller compartment, no trays |

| Height | Weight | Features |

|---|---|---|

| 925 mm | 118 kg | T-pad bracket, controller compartment, three trays |

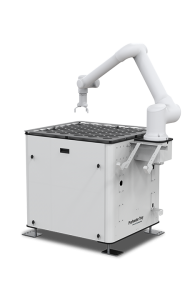

ProFeeder Series

ProCobot’s ProFeeder series, integrated with a collaborative robot arm from Universal-Robots, enables factories to implement a standardized Robot Cell that’s movable inside the factory taking the hassle out of integrating and designing a customized robotics cell. The ProFeeder system is a flexible and scalable solution that’s easy to setup and convert to new jobs. Profeeder PF Plus software is built around a database of trays, tools and part configurations. This eliminates the need to program the Universal Robot when changing jobs

ProFeeder Tray

Robot Machine Tending

- Heavy-duty design

- Large worktable

- Extruded aluminum top

- Optional leveling castors

Specifications

| Height | Width | Length | Weight | Features |

|---|---|---|---|---|

| 900 mm | 800 mm | 1165 mm | 202 kg | T-Pad bracket, Controller mount bracket, 80x80mm squares (56) grid plate |

ProFeeder

- The ProFeeder robot cell consists of 2 movers which act as pallet changers

- Manual changeable part tray

Specifications

| Height | Width | Length | Weight | Features |

|---|---|---|---|---|

| 932 mm | 1125 mm | 900 mm | 250 kg | T-Pad bracket, Controller mount bracket, 80x80mm squares grid plate |

ProFeeder X

- 5 or 10 drawer systems available

- 3-position drawers for continuous production

- High capacity with compact footprint

Specifications

| Height | Width | Length | Weight | Trays | Max part height | Features |

|---|---|---|---|---|---|---|

| 1050 mm | 980 mm | 920 mm | 430 kg | 5x 550×350 mm | 160 mm | T-Pad bracket, Controller compartment, 2.5mm deflection at 120kg/tray, with pneumatic locks |

| Height | Width | Length | Weight | Trays | Max part height | Features |

|---|---|---|---|---|---|---|

| 1050 mm | 980 mm | 920 mm | 550 kg | 10x 350×550 mm | 80 mm | T-Pad bracket, Controller compartment, 2.5mm deflection at 120kg/tray, with pneumatic locks |

Specifications

| Height | Width | Length | Weight | Trays | Max Part Height | Features |

|---|---|---|---|---|---|---|

| 1050 mm | 980 mm | 920 mm | 430 kg | 5x 350x550mm | 160 mm | T-Pad bracket, Controller compartment, 2.5mm deflection at 120kg/tray, pneumatic locks |

| Height | Width | Length | Weight | Trays | Max Part Height | Features |

|---|---|---|---|---|---|---|

| 1165 mm | 770 mm | 920 mm | 495 kg | 10x 350x550mm | 80 mm | 2.5mm deflection at 120kg/tray, pneumatic locks |

ProFeeder Flex

A robot pedestal with removable trays that can be easily moved between work stations.

Specifications

| Height | Width | Length | Weight | Features |

|---|---|---|---|---|

| 1100 mm | 680 mm | 1000 mm | 100 kg | Heavy duty caster wheels, Floor docking, T-Pad bracket, Controller compartment |

| Height | Width | Length | Weight | Features |

|---|---|---|---|---|

| 1100 mm | 680 mm | 1000 mm | 115 kg | Heavy duty caster wheels, Floor docking, T-Pad bracket, Controller compartment |

| Height | Width | Length | Weight | Features |

|---|---|---|---|---|

| 1100 mm | 1522 mm | 1096 mm | 150 kg | Heavy duty caster wheels, Floor docking, T-Pad bracket, Controller compartment |

ProFeeder Alu

- Compact design

- Specious tabletop

- Versatility of use

Specifications

| Height | Width | Length | Weight | Features |

|---|---|---|---|---|

| 932 mm | 800 mm | 1165 mm | 205 kg | T-Pad bracket, Controller mount bracket, 40mm Aluminum profile tabletop |

EasyDesk

Introducing EasyDesk, the all-inclusive robotic workstation. This innovative platform boasts ample space while maintaining a compact design, featuring three distinct tabletops. Designed to be compatible with 99% of contemporary collaborative robots, EasyDesk serves as a manufacturing solution that enhances productivity, streamlines automation, bolsters profitability, and diminishes labor costs.

EasyDesk stands as a user-centric series of robot cells, harmoniously compatible with 99% of present-day collaborative robots, CNC machines, and various conveyor belt configurations. Meticulously crafted, its purpose is to uncomplicate the process of automation and expedite an extensive array of production tasks.

EasyDesk Tray

- Customizable tabletop

- Double doors for quick access to robot compartment

- Variable robot mount location

Specifications

| Height | Width | Length | Weight | Features |

|---|---|---|---|---|

| 902 mm | 1550 mm | 890 mm | 330 kg | T-Pad bracket, Compartment for controller, 45-degree angle robot base, includes standard grid tray with 94 teardrop pockets (70mm diameter) |

EasyDesk Weld

- Plasma nitrided steel tabletop

- 16mm holes for fixtures

- Double doors for quick access to robot compartment

- Variable robot mount location

Specifications

| Height | Width | Length | Weight | Features |

|---|---|---|---|---|

| 972 mm | 1550 mm | 890 mm | 420 kg | T-Pad bracket, Compartment for controller, 45 degree angle robot base, perforated plasma nitrided steel plate, 1200x800x12mm |

Palletizing

EasyPalletizer: a mobile and space-efficient palletizing solution meticulously crafted to simplify palletizing tasks within factory settings. This system is rooted in the renowned industrial design and functionality that characterizes all EasyRobotics products, known for their steadfast stability and resilient construction.

EasyPalletizer

- Includes 835mm fixed pedestal

- EasyPalletizer One: fits UR, Hanwha, Omron cobots

- EasyPalletizer Two: fits Fanuc, Kassow, Doosan cobots

- Two programmable, multi-color lights

- Four pallet detection sensors on each side

Specifications

| Height | Width | Length | Weight | Features |

|---|---|---|---|---|

| 835 mm | 870 mm | 1350 mm | 200 kg | For 2 pallets with 4 sensors and 2 configurable LED lights, Extender kit |

| Height | Width | Length | Weight | Features |

|---|---|---|---|---|

| 835 mm | 870 mm | 1350 mm | 215 kg | For 2 pallets with 4 sensors and 2 configurable LED lights, Extender kit |

EasyPalletizer Pro

- Available with 835mm or 1200mm fixed pedestal

- Robot controller compartment with sliding rails

- Best option for 20kg payload cobots

- Two programmable, multi-color lights

- Four pallet detection sensors on each side

Specifications

| Height | Width | Length | Weight | Features |

|---|---|---|---|---|

| 1402 mm | 900 mm | 1850 mm | 310 kg | For 2 pallets with 4 sensors and 2 configurable LED lights, 1 cardboard holder, Modbus |

| Height | Width | Length | Weight | Features |

|---|---|---|---|---|

| 1402 mm | 900 mm | 1850 mm | 325 kg | For 2 pallets with 4 sensors and 2 configurable LED lights, 1 cardboard holder, Modbus |

ADDRESS

1 Technology Way

Indianapolis, IN 46268