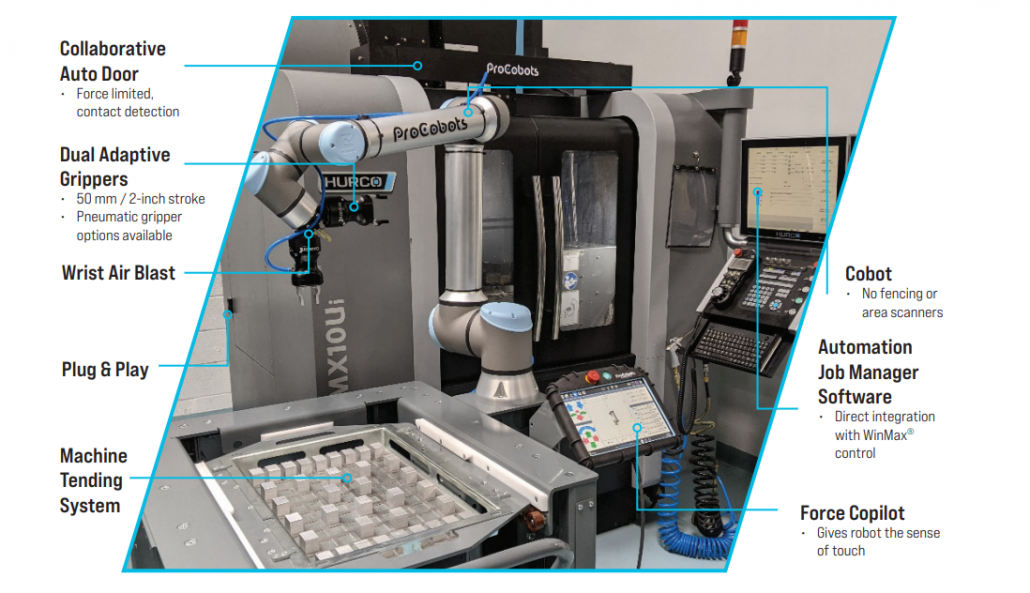

Machine Technology: Standard System Features

Machine Technology: Hurco Conversational Job Manager

Plug and play network-based Industry 4.0 Hurco Job Manager is seamlessly integrated with the Hurco WinMax Control to handle all your high-mix production needs. The Job Manager runs right on the Hurco WinMax control for both machining centers AND lathes.

No robot programming is needed. Just enter your part dimensions, select where the stock material is in the grid tray, select your part program, and RUN!

Compatible with v10.2 or greater WinMax Mill Max 5 Rev G controls; and v11.1 or greater Winmax Lathe controls.

Integrated Hurco Job Manager Force System

Intuitive software accesses the full capabilities of the UR e-Series embedded force torque sensor. The robot force system gives the robot the sense of touch, to reliably load parts using positive stops, stack parts, and press on them while actuating the work holding.

UR10e Collaborative Robot

Collaborative robot stops on contact. Safe and easy to use. 51” reach with 27.5 lb payload capacity. UR10e is fully integrated with Hurco’s Conversational Job Manager.

NO ROBOT PROGRAMMING NEEDED!

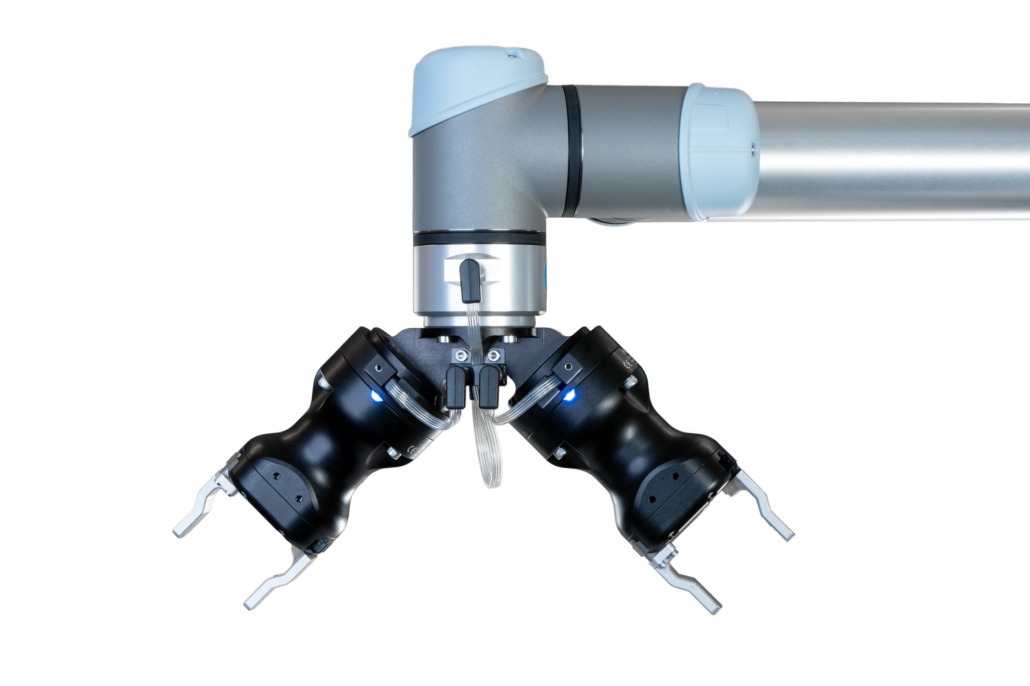

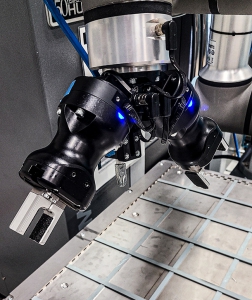

Dual Robotiq Hand-E Gripper

The Hand-E Gripper offers fully programmable finger position, speed, and gripping force, to meet a wide range of part handling needs. The second gripper optimizes cycle times, as the robot can remove a finished part and load new material with a single move into the CNC machine. The gripper has a 1.97” stroke, with grip force from 4.5 -41.5 lbf.

Hand-E Gripper Details

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera

- Ergonomic shape for hand-guiding

- Intuitive interface for quick onboarding and use

- No training required

- Automatic part detection, position feedback, and part validation

- Precise and durable

- High force and payload

- Withstands harsh manufacturing conditions

Part Stacking

Multiply your unattended run time by stacking parts! Total stack height determined by depth of grip.

Front Loading Collaborative Auto Door System

Force sensing auto doors with covers provide safe and silent door operation. The built-in collision detection system will reverse the door motion immediately on contact – just like an elevator door! Doors can be manually opened and closed when the motor is not energized.

Wrist Blow-off

Blow off part and vise or chuck jaws. This unit includes bracket and nozzle mounted to the wrist or gripper, and an additional pneumatic solenoid valve.

Interchangeable Grid Trays

A standard grid tray is included, with an 8 x 9 pocket grid, 3.15” x 3.15”, for a total of 72 grid pockets. With the Hurco Job Manager, there is no need to recalibrate anything when trays are changed. Simply enter the number of pockets and the pocket dimensions – the Job Manager does the rest!

Easy Access Pneumatics Control Panel

Easily accessible pneumatics control panel, to manage vise clamping pressure

Machine Interface Kit

- Quick Connect Machine Receptacle

- Quick Connect Robot Plug

- E-Stop Cap, to run your machine WITHOUT the Robot

- Electrical Interface Box

Hurco: A Leader in Machine Technology with WinMax® CNC Control

In today’s rapidly changing manufacturing industry, machine technology plays a crucial role in ensuring that businesses remain competitive and profitable. CNC machine tools have revolutionized the manufacturing process, enabling greater precision, accuracy, and efficiency in operations. Among the industry leaders in CNC machine tools is Hurco, a company that has gained a reputation for producing innovative and high-quality machines that meet the demands of the modern manufacturing world.

One of the key factors that sets Hurco apart from its competitors is its WinMax® CNC control system. This powerful software platform provides users with a range of features and functionalities that make it easier to program and operate CNC machines. With its user-friendly interface, intuitive navigation, and advanced programming capabilities, WinMax® has become a popular choice among operators, programmers, and engineers alike.

But it is not just the WinMax® CNC control that has helped Hurco to establish itself as a leader in machine technology. The company’s commitment to innovation and excellence is reflected in every aspect of its operations, from its product design and manufacturing processes to its customer service and support. This is exemplified by Hurco’s recent introduction of a flexible automation solution package, which further demonstrates the company’s commitment to providing cutting-edge machine technology to its customers.

The flexible automation solution package (Hurco + ProCobots) is a turnkey solution that allows manufacturers to automate their operations quickly and easily. It includes a range of features and functionalities that help to streamline production processes and improve overall efficiency. This includes all the system features mentioned above. With this package, manufacturers can automate repetitive tasks, reduce cycle times, and improve overall product quality, all while freeing up staff to focus on more critical tasks.

Hurco’s commitment to innovation and excellence is reflected not just in its products, but also in its customer support and service. The company has a team of experienced engineers and technicians who are available to assist customers with any technical issues or challenges they may encounter.

Additionally, Hurco offers extensive training and education programs to help customers get the most out of their machines and optimize their operations for maximum efficiency and productivity.

ADDRESS

1 Technology Way

Indianapolis, IN 46268